Cornerstone Timberframes delivers mass timber structures that meet the highest standards of

performance, sustainability, and aesthetic value. In collaboration with our supply partner, Nordic

Structures, we proudly utilize black spruce for our mass timber elements — a material that

continues to prove itself as a superior and cost-effective alternative to Douglas Fir.

Why Black Spruce?

1. Reduced Cost Without Compromise

Black spruce offers structural strength ratings equivalent to Douglas fir at a lower material cost.

This creates notable savings, particularly when scaled to larger commercial, institutional, or

residential builds.

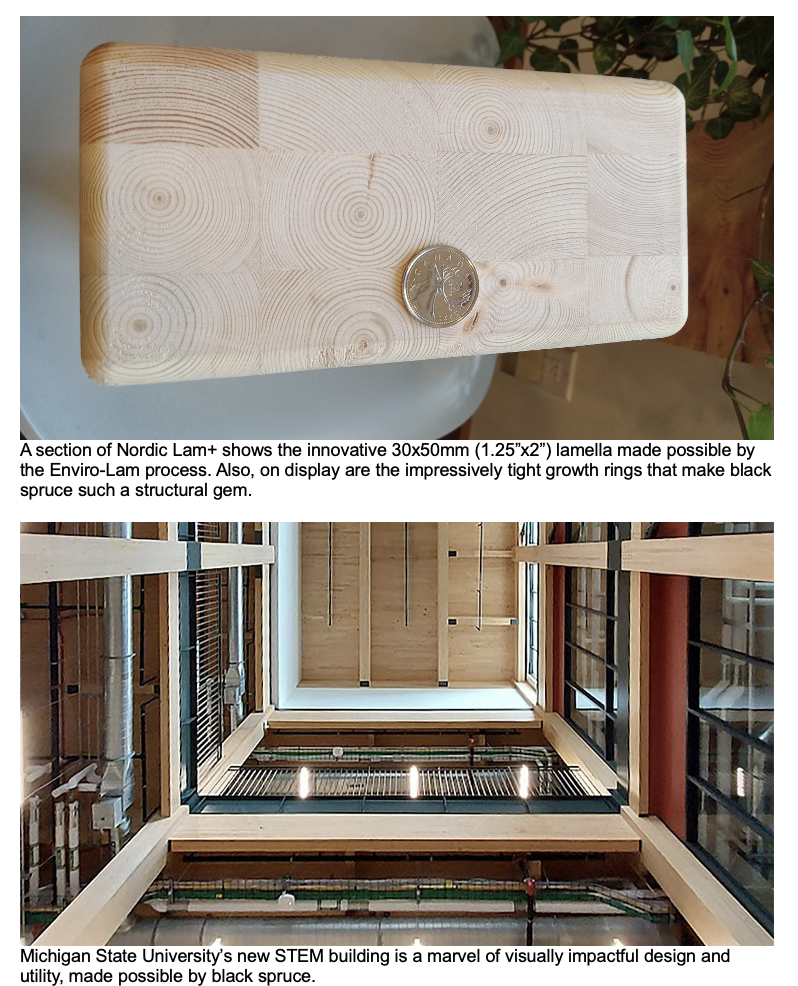

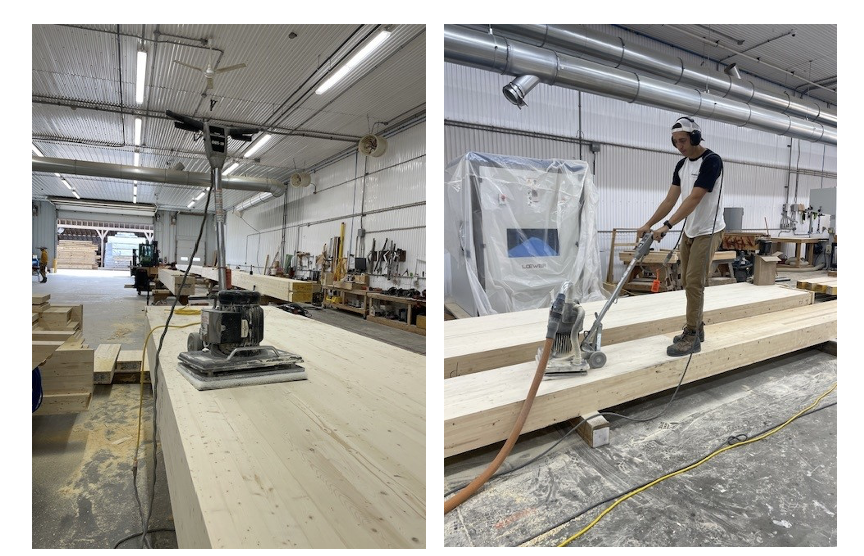

2. Superior Dimensional Stability

The tight grain and small laminations in black spruce glulam result in increased dimensional

stability, reduced checking, cupping, and twisting over time.

3. Improved Colour and Appearance

Black spruce is known for its uniform appearance and light colouration. Its superior ability to

receive stain and faithfully render colours makes for creative freedom and a higher architectural

appearance. In comparison, fir’s red undertone and tendency to have light and dark alternating

stripes create aesthetic limitations.

4. Locally Sourced & Sustainably Harvested

Grown and manufactured in Canada, black spruce is a renewable resource harvested from well-

managed forests in Quebec. Both Cornerstone Timberframes and Nordic Structures are FSC®

certified, choosing to follow the most rigorous sustainable forestry program in Canada.

5. A Decarbonizing Hero

Black spruce is uniquely suited to help Canadians decarbonize construction. At about age 80

black spruce is mature and begins to decline in health, moving from absorbing carbon to

releasing it back to the atmosphere. Nordic harvests mature black spruce, locking their carbon

into durable mass timber products. In contrast, Douglas Fir trees live for over 300 years,

absorbing C0 2 throughout their long lives. It is vital to preserve long-lived trees as carbon sinks

if we hope to reach a carbon-neutral future.